- #Install riving knife on old craftsman table saw pdf

- #Install riving knife on old craftsman table saw series

- #Install riving knife on old craftsman table saw free

Second the cut I got was as clean as if it had been made on a jointer. First I no longer had to try to push the piece forward and against the fence, once the piece hits the riving knife, the knife keeps it against the fence - one less thing to distract you from the spinning blade. When I finally fired the saw up and cut a test piece, it was like I was using a new saw.

This made it easier to position and I figured I would get a cleaner cut on the keeper side for me usually the piece between the blade and the fence on the work piece. Make a Riving Knife for the DW745 Tablesaw Since the knife is slightly narrower than the blade, rather than trying to center the knife, I decided to bias the knife position towards the fence side. By varying the number of shims between the trunnion arbor assembly and the knife it centers the knife on the blade.

#Install riving knife on old craftsman table saw series

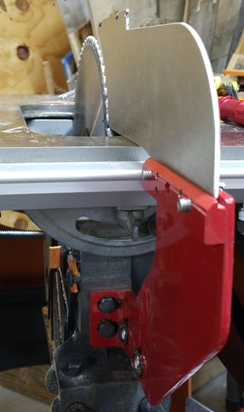

The knife is held in place by a plate with two bolts.īetween the plate and the trunnion arbor assembly are a series of thin shims. Then I concentrated on getting the knife aligned with the blade. Once I was satisfied with the fit of the riving knife, I removed it once more and gave it a coat of paste wax to protect the metal and make the knife slippery. I spent a lot of time going between the sander and my table saw checking the fit of the knife. The jig saw left a really ragged cut line, so I tried using my bench grinder to shape the metal. I decided not to cut the guard mounting slots on top of the knife, because I did such a poor job on the simpler slots. I messed this part up pretty badly, still I got the riving knife to work. For the mounting slots, I drilled a hole at the top and cut the rest of the slot with the jig saw. As I cut around the outline with my jigsaw, I shredded the pattern, but somehow I still managed to cut out the right shape. This was probably a mistake, I should have traced the pattern with a Sharpe instead. Once I got the steel in the mail a few days later, I printed out the pattern, verified that the dimensions were correct, then glued the pattern onto the steel.

#Install riving knife on old craftsman table saw pdf

After reading the entire site, I found PDF of the riving knife pattern.Īfter looking at that pattern and examining my factory guard, I thought I could make my own, using this pattern. There was one problem, right on the home page it said lead times were 8 to 10 weeks. They also sold just the riving knife for my saw. After searching, I only found one company that makes custom riving knives, splitters, and guards for my table saw: Leeway Workshop LLC. After seeing this video though, I started looking for a way to retrofit my DeWalt with a riving knife. The board and push block flew out of his hands and his hand almost kissed the saw blade. In the video he pushed a board through his table saw without a riving knife and twisted it at the end of the cut. Your email address will not be published.May 01 Print this Post. Please contact if interested in riving knife. We have just designed a riving knife for this saw. Only need a splitter or riving knife? In the works.

Model numbers for this package are below. You may order here, then send us an email to confirm your model number so we know exactly what setup you will need.

#Install riving knife on old craftsman table saw free

Making installation is a tool free operation! As always, fill out an inquiry when placing an order. The riving knife mounted guards on newer table saws attach the same as the OEM did, and can be left installed for dado cuts as they can be adjusted below the top of the teeth of the blade. You will no longer need the standard rear splitter mount should be removed. This helps to cut off the air flow at the base of the guard and aids in dust collection - it attaches behind the blade below the throat plate. The different height splitters are for different thickness stock. Our splitters are 3 different heights, two for attaching the guard to and one stubby for non through cuts. Only need pawls? Find them here! This setup includes the original SharkGuard dust collecting blade guard, clamp assembly, and suitable splitter or riving knife for your particular model. Only need a splitter? Find it here! Please write us with your make and model number expect a customer service call within 24 hours. Installation is a tool free operation! Craftsman 979941001 Table Saw Riving Knife You will no longer need the standard rear splitter mount can be removed. Our splitters are 3 different heights and attaches behind the blade below the throat plate.

Everything you need in one package! This setup includes the original SharkGuard dust collecting blade guard, and a suitable splitter set or riving knife.

0 kommentar(er)

0 kommentar(er)